Large-scale aerobatics with a wallet-friendly price

Photos by the author and Jon Barnes

WATCH IT FLY

An extremely high power-to-weight ratio allows for extended hovering and rocket-like punchouts.

WHEN I FIRST STARTED flying RC airplanes, I was bombarded with multiple axioms from veterans in the hobby. Although many were helpful, one in particular has withstood the test of time: bigger flies better.

Generally speaking, the larger a model is, the more stable it will be in the air, the less it will be affected by wind, and the easier it will be for pilots to maintain visual orientation. Taking this to its logical conclusion, FMS, a company well known for producing a wide range of foam models, has released its largest foam 3D/aerobatic airplane to date: the 2000mm Extra 330 PNP.

With a wingspan (and length) of roughly 79 inches and a wing area of more than 1,260 square inches (placing it in the 27%-scale category), this Extra 330 is huge. Choosing the Extra 330 as the platform for such an ambitious move makes perfect sense. The Extra, in its many variations, is a tried-and-true airframe. Known for its precision, as well as its ability to perform nearly any aerobatic maneuver you can think of, the Extra design provides an extremely wide flight envelope.

Having some experience with large-scale 3D/aerobatic models, I was happy to hear that a company was willing to take the leap and offer a lower-cost, foam-based option. Purchasing a 27% wood airframe along with the motor, ESC, servos, etc., would cost significantly more money.

Assembly

Although the build process is quick and straightforward, a few points deserve extra attention. Sanding the carbon-fiber spar might be necessary in order for it to slide easily through the tube in the fuselage and into the wing. If so, go easy and take your time so you don’t remove too much material.

Do not force the wing or the stabilizer/elevators into the fuselage. The fit was extremely tight, requiring some elbow grease to fully seat them. This is ultimately good because a rigid airframe improves flight performance, but forcing the fit during assembly could cause damage.

Some adjustment was necessary to achieve a neutral control-surface position and 90° servo arms. Rotating the ball-link ends a few turns in or out will get you in the ballpark. (Ideally, the elevator linkages should be perfectly symmetrical.) Remember to use some threadlocker on the ball-link hardware to protect against vibration-induced loosening.

Specifications

Model type: Electric 3D/aerobatic

Skill level: Intermediate to advanced pilots

Wingspan: 78.7 inches

Wing area: 1,263 square inches

Length: 78.9 inches

Wing loading: 23.9 ounces per square foot

Cube loading: 8.1

Weight: 210 ounces

Power system: Brushless electric outrunner

Radio: Spektrum iX12

Construction: EPO foam

Price: $659.99 for plug and play; $429.99 for kit

Test-Model Details

Power system: 6860 240 Kv brushless outrunner; Predator 90-amp HV with external SBEC (included)

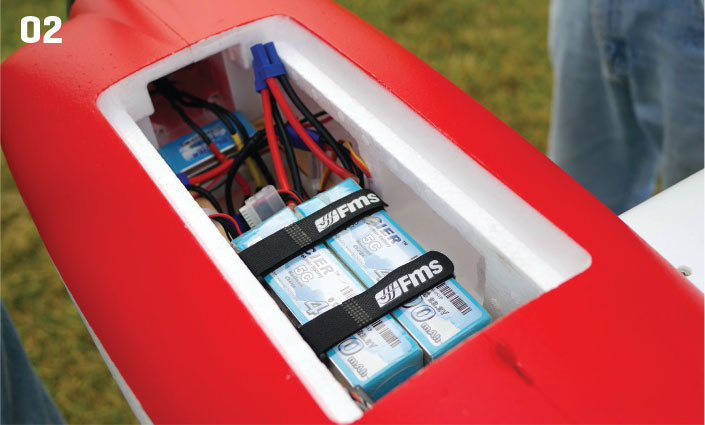

Battery: Two Glacier 6S 45C 4,000 mAh 12S LiPos

Propeller: 20 × 8 FMS Beechwood (included)

Receiver: Spektrum AR8000 DSMX with satellite

Servos: Five Power HD WP-23KG digital metal-gear servos

Ready-to-fly weight: Approximately 210 ounces

Flight duration: 5 to 7 minutes

Pluses

Lightweight EPO foam is rigid, durable, and easy to repair.

Wide flight envelope includes sport, precision, and 3D.

Its large size provides stability and impressive airborne presence.

A simplified assembly process shortens the unboxing-to-flying timeframe.

Minuses

Tight wing-to-fuselage fit requires some effort during wing installation and removal.

Carbon-fiber wing spar required sanding for smooth installation in fuselage and wing tubes.

FMS Model

Set your maximum control-surface deflections using your radio’s servo travel adjustment instead of trusting your radio’s default settings. After you’ve set the deflections and confirmed that there is no binding, you can set your rates and exponential.

For those who don’t have experience setting up a dual-elevator tail, the process can feel intimidating, but modern computerized radios handle these situations quickly and efficiently. With no retractable landing gear or flaps on this model, pilots can utilize a six-channel receiver and select both dual aileron and dual elevator in their radio’s wing-type menu.

Ailerons will plug into the Ail/Aux1 channels, and elevators will plug into Ele/Gear channels. (Splitting both ailerons and elevators into separate channels allows for separate reversing, subtrim, and servo travel adjustments.) Make sure that the linkages and servo arms for both halves are set nearly identical then use subtrim to set surfaces at neutral.

Fully deflect the elevators up and down and note which one terminates higher or lower than the other. Enter your radio’s servo setup menu, select servo travel, and increase or decrease the low or high half to match the other half.

FMS has outfitted the Extra 330 with five high-torque, digital, metal-geared Power HD WP-23KG servos. These waterproof servos provide a whopping 319 ounces per inch of torque at 6 volts. Power is managed through a Predator 90-amp, high-voltage (HV) ESC, with an external BEC that is adjustable via a switch, to between 5.5 and 8.4 volts. (The HV option should only be used with HV servos and a receiver capable of handling at least 8.4 volts.)

Powering this Extra is a soup-can-size, 6860 brushless outrunner motor. At 240 Kv, the motor spins slightly fast for 12S; however, FMS compensates by utilizing a 20-inch propeller with a moderate pitch to keep the current draw in check. (Designing this model as a 12S instead of a 10S setup, FMS shows it has its finger on the pulse of the RC flying community. How many fliers do you know who have several large-capacity 5S packs at the ready?)

With two matched Glacier 6S 4,000 45C LiPo battery packs running in series and the stock propeller, the motor pulled 94 amps or 3,800 watts during bench testing. The model tips the scales at 210 ounces, resulting in a mind-blowing power-to-weight ratio of approximately 280 watts per pound. (The antiquated 3D/aerobatic standard for "unlimited vertical" has long been 200 watts per pound.)

The manual recommends balancing the model fully loaded under the wing, in an upright orientation, between 5-2/3 and 6 inches aft of the wing’s leading edge. Using two 6S 4,000 mAh battery packs weighing 590 grams apiece, I was able to achieve an appropriate balance with the packs set 1/2 inch forward of center on the easily accessible battery tray.

Flying

After my standard preflight process of range testing, bind-free servo deflection checks, and propeller tightness, I taxied the model up and down the runway to get a sense of its ground handling and to what extent its massive 5-inch wheels were affected by the dirt and gravel surface.

Unencumbered by wheel pants, the model’s big tires appeared capable of managing dirt, gravel, grass, and snow-covered surfaces. With this Extra 330’s significant rudder deflection, its turning radius is tight and helpful, particularly given our barely 20-foot wide runway. With ground-handling testing behind me, I selected precision rates and powered the big Extra down the runway for a scalelike takeoff.

Although this Extra 330 is not marketed as a sport model, some pilots might purchase it as such.

The 20-inch Beechwood propeller’s low pitch grabbed big scoops of air and pulled the 13-plus-pound aircraft up with ease. Having such large, foam control surfaces, which can be prone to warping, I expected the model would require significant trimming; however, surprisingly little was required to achieve level, upright flight. My process for testing a new model is fairly consistent: trim, test the in-flight center of gravity (CG), and test the coupling.

Having established level flight, with zero pitch changes regardless of airspeed, I rolled the airplane inverted to get a sense of its CG. With my matched pair of Glacier 45C 6S 4,000 mAh LiPo battery packs placed as I had previously mentioned, the model required only a small amount of pressure on the elevator stick to maintain level, inverted flight.

With trimming and CG testing completed, I rolled the Extra into a knife-edge maneuver to test for unwanted pitch/roll with the application of rudder. Fortunately, the model exhibited little coupling. Should you find any, use your modern, computerized radio to dial in a few percentage points of rudder-to-aileron and rudder-to-elevator mix.

A well-designed 3D/aerobatic model should have a flight envelope that covers the three fundamental cornerstones of 3D/aerobatic flight: precision, post-stall, and extreme aerobatics. For example, if a model is unable to cleanly transition from a precise knife-edge pass into a violent tumble and end in a stable harrier, I’m less likely to bring it to the field. Perfection in each area is not necessary; however, if a model is noticeably deficient in one area (imagine a three-legged stool with one short leg), the defect will bleed into all areas of flight performance.

With this in mind, I’ll admit to entering the flight-testing with somewhat mild expectations. This Extra 330 is, after all, a foamie. Several flights later, I was wiping away humble pie crumbs with a grin!

Sport

Although this Extra 330 is not marketed as a sport model, some pilots might purchase it as such. With this in mind, I spent some time during the initial flights cruising around the field and flying basic patterns (upright and inverted), with an occasional hammerhead or loop thrown in for good measure.

Flying fast, low-key knife-edge passes with nearly 80 inches of wingspan hurtling past you is downright thrilling.

Aside from feeling as though I was driving a Corvette around a parking lot, the model kept its composure and tracked beautifully. Given the airplane’s stable and docile nature, pilots who’ve only just achieved an intermediate level of skills would likely find the model easy to fly.

Precision

With the model properly trimmed and balanced, and with little coupling to worry about, I was able to put the airplane through some of my favorite precision maneuvers. I began with four-point rolls, flying at speed and parallel to the flightline. I aimed for crisp, quarter rolls with 1-second pauses. The model tracked straight and true, requiring only small corrections. With such results, I had no doubt that slow rolls would also be successful although, instead of pausing at each point, the airplane should seamlessly enter into and out of each orientation.

Again, only minor corrections were required. Finishing with the knife-edge maneuver, I spent some time performing large, fast ovals, appreciating the model’s precision tracking. Flying fast and low knife-edge passes with nearly 80 inches of wingspan hurtling past you is downright thrilling.

3D/Aerobatics and Post-Stall Mannerisms

The combination of twin, high-torque servos with elevator halves of a size more often found on 50cc models results in pitch authority that can only be described as extreme. This amount of control allowed me to easily break the wing free and stall the airplane.

I found myself utilizing this pitch authority to put the model into one of my favorite maneuvers: an inverted elevator. Pushing and holding full down-elevator, the model sinks straight down inverted, as though in an actual elevator. When combined with a punch-out, the juxtaposition between this Extra’s furious full-throttle upline and its nearly silent, fully stalled float back to earth is as entertaining as it gets.

I generally try to test new airplanes with certain go-to maneuvers that allow me some comparisons. One such maneuver is the rolling harrier that tests a model’s post-stall mannerisms and reveals to what degree its rolls stay axial. (Ideally, the model’s spinner and tail stay on the same datum-line during the roll, as opposed to wobbling off track.) With the model’s large ailerons, I found that I was able to keep the Extra 330 rolling fairly quickly, at surprisingly slow airspeeds, and with a visually pleasing axial nature.

I spent some time holding the Extra in extended hovers and torque rolls. The giant ailerons allowed me to hold the hover as long as I wanted, and releasing them allowed the motor’s torque to spin the big Extra at will. Because an Extra’s swept-wing design is tailored to speed and precision, it gives up some post-stall stability; however, I found the Extra 330 to be surprisingly stable in both upright and inverted harriers, with low levels of wing rock. The model actually feels floaty after a stall.

Extreme Aerobatics

Tumbling maneuvers are perhaps the most popular component of 3D flight. Taking a fast-moving airplane into a stalled state and utilizing momentum in a violent but controlled manner can result in a lot of dropped jaws. Initial testing suggests this Extra 330 has solid tumbling credentials.

With its exceptional pitch authority, I had a blast performing repeated poptops and deep snaps, resulting in the model spinning tightly around its CG. Given its more moderate wing loading and large, lift-creating fuselage, I would not describe it as being positioned for the more violent end of the aerobatic spectrum. However, the model’s floaty and stable post-stall mannerisms are profoundly helpful for fliers who are stepping up to largescale 3D/aerobatics.

Conclusion

For those 3D/aerobatics pilots who have worked their way up to 60-size airframes and want to make the leap to large-scale aircraft without taking out a second mortgage, the FMS 2000 mm Extra 330 is ideal. Stable and floaty in post stall, surprisingly precise and accurate in its tracking, and capable of a wide range of 3D maneuvers, this visually pleasing model provides the added comfort that comes from durable and easy-to-repair EPO foam. At $659.99, this big Extra should be near the top of any bang-for-your-buck list.